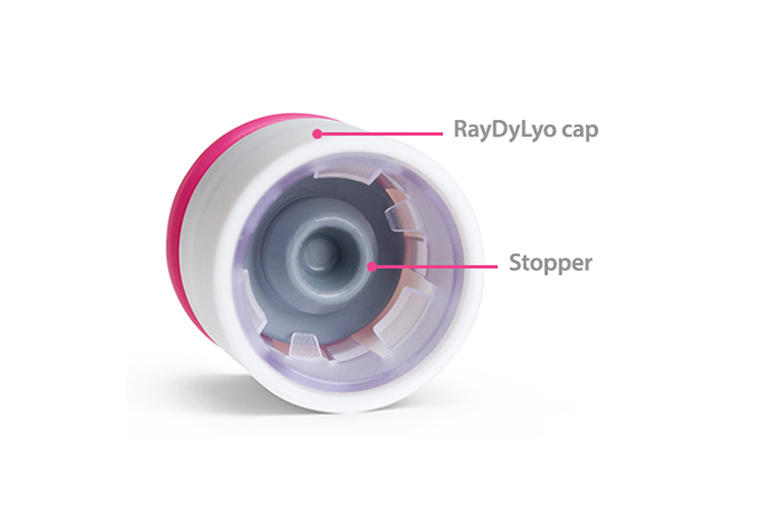

RayDyLyo® is the new all-plastic push-fit cap for closing vials of injectable drugs. Unlike alternative to the aluminum crimp cap, RayDyLyo® makes it possible to pre-assemble the stopper in the cap and simplify the production process. It allows pharmaceutical companies to accelerate the time to market of new drugs.

An ingenious system for new molecules

RayDyLyo® is the capping solution suited to the economic, technological and organizational challenges of the industrial plant of the future.

The RayDyLyo® range simplifies production processes and meets the need for flexibility of manufacturers of new molecules (cell therapies, biosimilars, oncology, monoclonal antibodies), from the development phase to mass production.

A new standard for vial capping

In response to regulatory changes, particularly in aseptic filling (Appendix 1 GMP), RayDyLyo® eliminates crimping for both liquid and lyophilized forms.

It is available in 13 and 20 mm diameters to suit different vial sizes.

Two versions are available: CTO (central tear-off) for injectable products and TTO (total tear-off, under development), for mixing and reconstitution of products.

Download the PDF file

RayDyLyo® brochure

• Suitable for ISO 8362-2 rubber stoppers, pre-validated by the customer

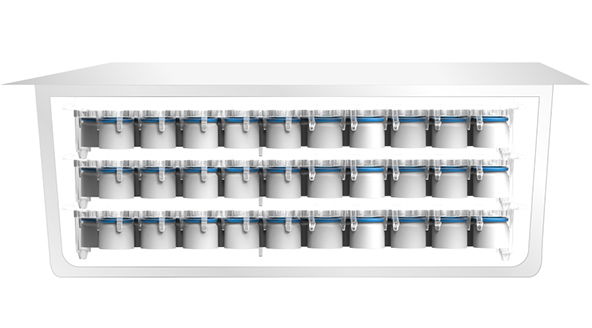

• Stoppers are pre-assembled automatically in the RayDyLyo® cap

- 100% camera in process control

- 100% control of stopper insertion

• Different packaging options: in standard bags, RTP type bags and nests

• Delivered sterile (RTU) or ready-to-sterilize (RTS)

• Compatible with gamma and steam sterilization

Anti-counterfeiting solution

• Patented solution

• Tamper evident features

• Colored flip cap cannot be re-installed

• Printing and labelling possible on cap body

True marketing differentiator

• 11 standard colors for the flip cap

• Ergonomic design

• Easy flip cap removal

• No risk of jagged metal edges damaging gloves

Compatibilty CTO 13

- Vials ISO 8362-1

- Lyo stopper ISO 8362-5

- Serum stopper ISO 8362-2

- Gamma sterilization

- Steam sterilization

Compatibilty CTO 20

- Vials ISO 8362-1

- Lyo stopper ISO 8362-5

- Serum stopper ISO 8362-2

- Gamma sterilization

- Steam sterilization

ARaymondlife has developed the essential accessory for drug reconstitution, the vial adapter, one for each RayDyLyo diameter.

Download the PDF file

See the video

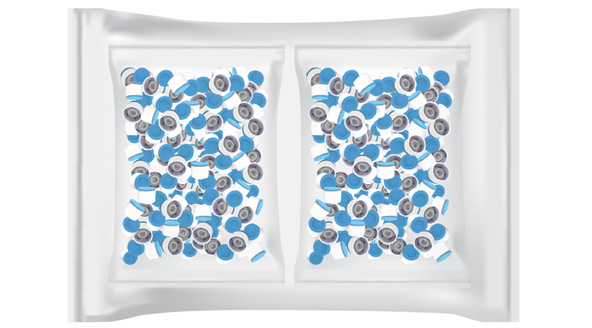

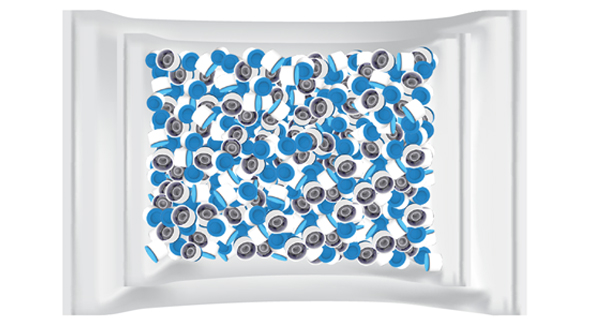

RayDyLyo is available in different packaging configurations

Different packaging options

|

Bulk packaging (pieces/bag) |

Ø 13 mm | Ø 20 mm |

|---|---|---|

Small bag  |

2 x 400 = 800 | 2 x 200 = 400 |

Big bag |

2000 | 1000 |

| RTP bag |

3200 | 1600 |

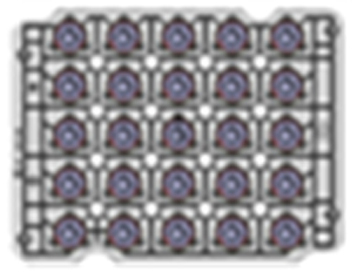

| Nested caps (pieces/nest) | Ø 13 mm | Ø 20 mm |

|---|---|---|

For 2R/4R vials |

100 | - |

For 6R/15R vials |

- | 48 |

For 20R/30R vials |

- | 25 |

For 50R vials |

- | 16 |

Nests are supplied in tubs of 3

Different uses of RayDyLyo®

RayDyLyo® is suitable for use manually in clinical batch production as well as filling in isolators and serial production on filling lines.

RayDyLyo® is suitable for clinical batch production and small batches. It allows filling and capping in the aseptic area. Manual capping is easy and safe needing only simple vertical pressure without any special tools. RayDyLyo® is fully tamper evident and eliminates cosmetic defects on closures.

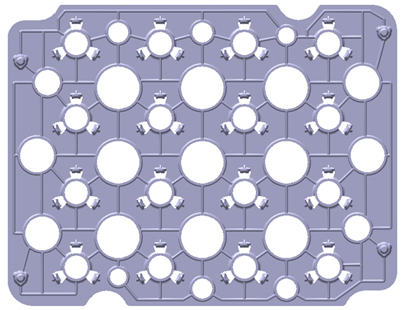

RayDyLyo® caps are available in nests Ready-To-Use in different sizes which are compatible with commonly used nested vials. Nested caps enable gloveless filling and capping in one single step in a controlled aseptic production environment without de-nesting. Quick change over between cap sizes is easy.

RayDyLyo and SCHOTT adaptiQ nest

Aseptic Filling Solution

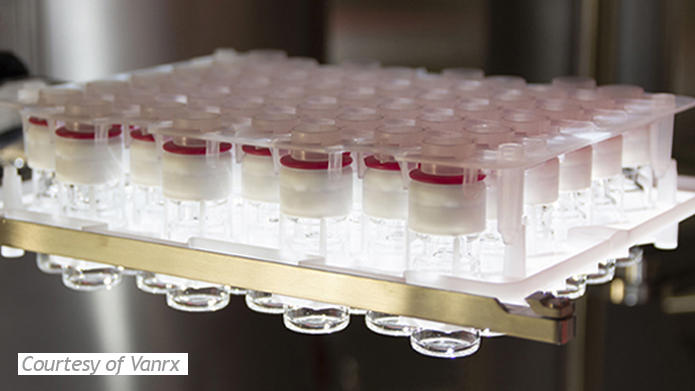

ARaymond, SCHOTT, and Vanrx have teamed up to design an aseptic filling solution that uses a fully automated isolator.

The ARaymondlife RayDyLyo® nested solution is available in :

- Ø20 mm for 6 to 50R vials

- Ø13 mm for 2 to 4R vials

The ARaymondlife RayDyLyo® nested solution is fully compatible with adaptiQ® nested vials designed by SCHOTT.

Nesting allows manipulation within a completely automated isolator: a nest of vials is filled and then closed with a nest of RayDyLyo® caps in one operation, without de-nesting.

Vancouver-based Vanrx Pharmasystems developed the SA25 and Microcell Aseptic Filling Workcells for use with injectable medicines.

Benefits

• No human intervention is necessary, which guarantees sterile filling.

• This RTU solution is unique: it guarantees sterile, reproducible manufacturing conditions.

• It offers greater flexibility - switching drugs between two production runs is faster - and is clearly a timesaver.

• Fast changeover between drug products

• Suitable for small to medium size batches

• No glass-to-glass contact

• Nested component products

• No need to de-nest for capping

See the video

In 2017, the Spanish company Dara Pharmaceutical Packaging worked closely with ARaymondlife to adapt its SX-310 filling line to work with RayDyLyo® closures. Equipped with a single vibratory bowl and specific format parts for feeding and capping with RayDyLyo , the SX-310-RDL line has a reduced footprint compare to conventional lines, whilst maintaining quality standards.

Convinced by this first success,DARA and ARaymondlife decided to modify a new line (NFL/2) for processing RayDyLyo® plastic push fit caps in 2018.

The NFL line is a line dedicated to the filling and capping of ready to use (RTU) nested vials, cartridges and syringes.

Collaboration with filling line manufacturers

Modifying our equipments to work with RayDyLyo® plastic caps was quick and easy, thanks to the close collaboration with ARaymondlife” says Joan Mele, Commercial Director at Dara Pharmaceutical Packaging. "Today we are able to offer 2 lines which are operational and ready to be marketed. In particular, the NFL/2-RDL is a compact and multi format machine that makes it possible to close vials in one step on line and without de-nesting, in an aseptic area thanks to RayDyLyo®.

Machine SX-310-RDL

Compact machine for automatic infeed, filling and closing of injection vials.

Download the PDF file

ARaymondlife DARA SX-310

Machine NFL/2-RDL

Filling and closing machines for vials in nest and RayDyLyo® caps.

Download the PDF file

ARaymondlife DARA NLF-2

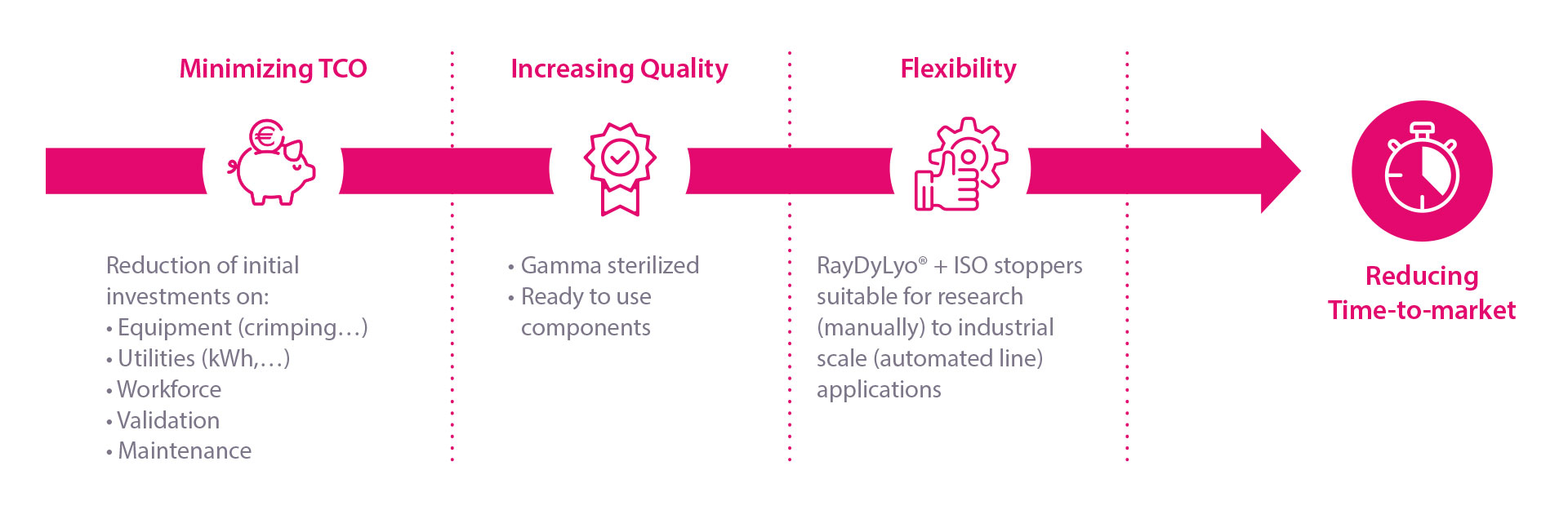

Added value of the solution