Press release:

A new approach in fill and finish

With ever more new pharmaceutical drug products entering the market, pharmaceutical companies

are facing new challenges when it comes to fill and finish. These processes now need to adapt to

different output speeds, changeover times or the ability to process nested containers i.e. syringes,

cartridges or vials on one filling line. In particular, pharma companies in biotech or cell and gene

therapy development as well as large pharma manufacturers with CMO activities are consequently

in need of flexible approaches in fill and finish. One such approach will be demonstrated at this year’s

CPhI Worldwide in Frankfurt, Nov. 5-7, by ARaymondlife, Groninger and SCHOTT at booth 111F10.

Courtesy of groninger

A versatile combination for more flexibility

To meet the growing demand for more flexibility in aseptic manufacturing, the companies are

bringing together adaptiQ® ready-to use (RTU) vials from SCHOTT, RayDyLyo® RTU plastic push fit

caps from ARaymond, and the Nestfiller machine portfolio from groninger.

The pre-sterilized, nested adaptiQ® vials are part of the SCHOTT iQ® platform. This holistic concept

standardizes RTU syringes, vials, and cartridges within a single tub format to run on the same filling

line, minimizing changeover times. All the components listed can be filled and closed with the

groninger Nestfiller portfolio from smaller outputs to high speed equipment.

The groninger Nestfillers are designed and built to handle all nested components by simply changing

format parts and thereby significantly reducing the machinery needed. In the case of existing

equipment, a retrofit from a syringe to nested vials or cartridges is possible by installing or exchanging

a set of format parts.

When running nested vials, the de-nesting and final closing with an aluminum cap on separate

equipment is still common, yet adds complexity and investment costs to the process. With RayDyLyo®

press fit caps this process is reduced to just one operation in nest.

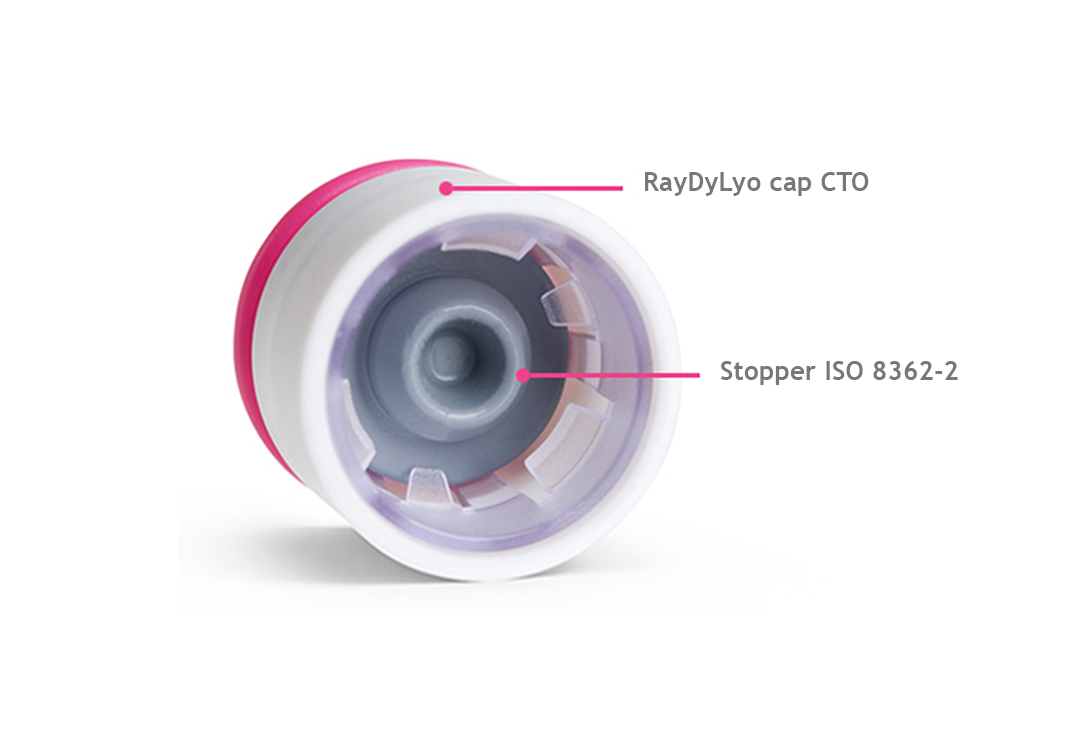

RayDyLyo® a new standard for vial capping

RayDyLyo® is an all-plastic capping solution designed to

work with all ISO stopper configurations (serum and lyo).

Customers select and validate the stoppers which are

assembled automatically by ARaymondlife. Pre-assembly of

the stopper in the RayDyLyo® cap upstream simplifies the

vial capping process to one-step directly in the filling area

and eliminates the constraints associated with the crimping

of aluminum caps.

Furthermore, ARaymond’s product allows groninger to

install press fit technology on new or existing equipment in

the same way a new nested format is mounted on the

machine, by exchanging the sorting parts on the filling

machine.

The combination of ARaymond, groninger and SCHOTT products is designed to meet the needs of

future fill and finish operations by providing maximum flexibility. Visitors to CPhI Worldwide can

explore the concept at ARaymondlife’s booth 111H51, groninger’s booth 110C10 and at SCHOTT’s

booth 111F10.

Media & Product Information Contacts

Members of the three companies will be attending CPhI Worldwide in Frankfurt from 5-7 November

2019. To request information on this approach, please contact:

About SCHOTT:

SCHOTT is a leading international technology group in the areas of specialty glass, glass-ceramics and

related high-tech materials. With over 130 years of experience, the company is an innovative partner

to many industries, including the home appliance, pharma, electronics, optics, life sciences,

automotive and aviation industries. SCHOTT has a global presence with production sites and sales

offices in 34 countries. In the 2017/2018 fiscal year, the group generated sales of EUR 2.08 billion

with over 15,500 employees. SCHOTT AG has its headquarters in Mainz (Germany) and is solely

owned by the Carl Zeiss Foundation. This is one of the oldest private and largest science-promoting

foundations in Germany. As a foundation company, SCHOTT assumes special responsibility for its

employees, society and the environment. www.schott.com/iQ

About groninger:

groninger is one of the world's leading manufacturers of filling and sealing machines for the

pharmaceutical, cosmetics and consumer healthcare industries. The slogan "We fill Visions with Life"

aptly describes what groninger stands for: excellent know-how, innovative solutions and partnershipbased

cooperation in the special engineering sector. Since it was founded by Horst Groninger in 1980

the company has become a hidden champion and innovation leader in the industry. Today the

company, managed by the family's second generation, employs around 1,300 people at its sites in

Crailsheim, Schnelldorf and Charlotte (USA). The company headquarters is in Crailsheim.

www.groninger.de

About ARaymond:

ARaymondlife is a company of ARaymond Network dedicated to the development of packaging

solutions for the healthcare market. With more than 7,000 employees in 25 countries worldwide, the

ARaymond Network designs, manufactures and markets fastening and assembly solutions for

industry. Founded in 1865, this French family firm has always put people at the heart of its success.

Guided by innovation and value creation, the ARaymond Network is one of the global leader in

fastening and assembly solutions for the automotive market. www.araymond-life.com

Key figures:

President: Antoine Raymond

Annual revenue for 2018: €1.2 billion

7,200 employees in 25 countries on 4 continents

Trademarks

adaptiQ® is a registered trademark of SCHOTT AG.

RayDyLyo® is a registered trademark of ARaymond